SERVICE

Service

Service process

Service Process

01 Feasibility Analysis

(Drawing Evaluation, Negotiation, Communication)

Evaluate, negotiate, and communicate based on the processing requirements of the product drawings.

02 Process Design and Analysis

(Mold and Fixture Design, Programming)

Design molds and fixtures, and write programs based on the processing requirements of the product drawings.

03 Mold and Inspection Fixture Development

Develop molds and inspection fixtures based on the requirements of the product drawings.

04 Sample Production

Produce samples according to customer requirements.

05 Sample Inspection

Provide complete inspection data for the samples to facilitate customer confirmation.

06 Packaging and Shipping

Package according to customer specifications and deliver the finished products to the customer.

07 Customer Acceptance

Perform acceptance testing according to the customer's in-house acceptance standards.

08 Mass Production and Continuous Improvement

Conduct mass production and continuously optimize the process.

01

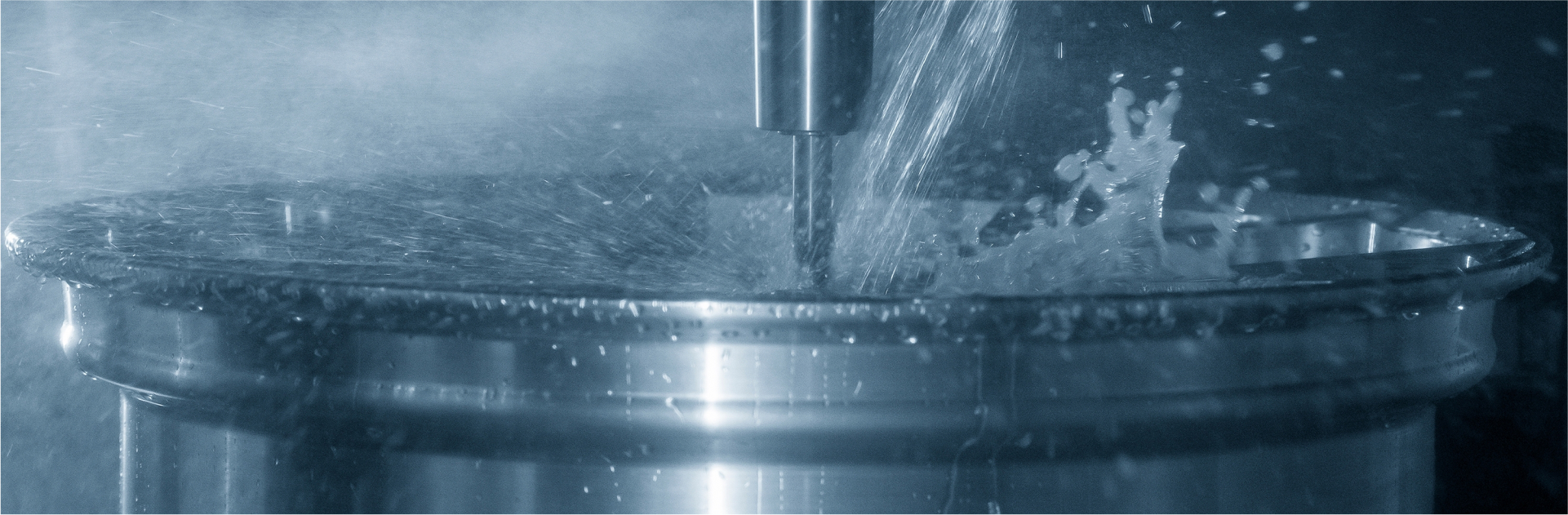

CNC Milling (Mass Production)

Improve precision to better meet customer requirements.

Processing Range: MAX 1100mm Number of Machines: 8

All equipment uses "Computer Numerical Control" (CNC) milling machines for processing. These machines utilize a digital computer system and programmed inputs to drive the CNC milling mechanism for precise machining. CNC milling features include the ability to machine flat surfaces, grooves, gears, threads, and spline shafts, as well as more complex curved surfaces. This greatly enhances production efficiency and significantly improves part processing accuracy, while also minimizing human error during large-scale CNC milling operations.

Our CNC milling machines have a fourth axis and central coolant functionality. This not only greatly shortens processing time but also enhances precision to meet customer requirements better.

We offer manufacturing and processing of various components, including:

- Linear guides

- Linear blocks

- Automation equipment

- Semiconductor fixtures

- Medical equipment

- Robotic arm parts

- Power tools

- Automotive and motorcycle components.

02

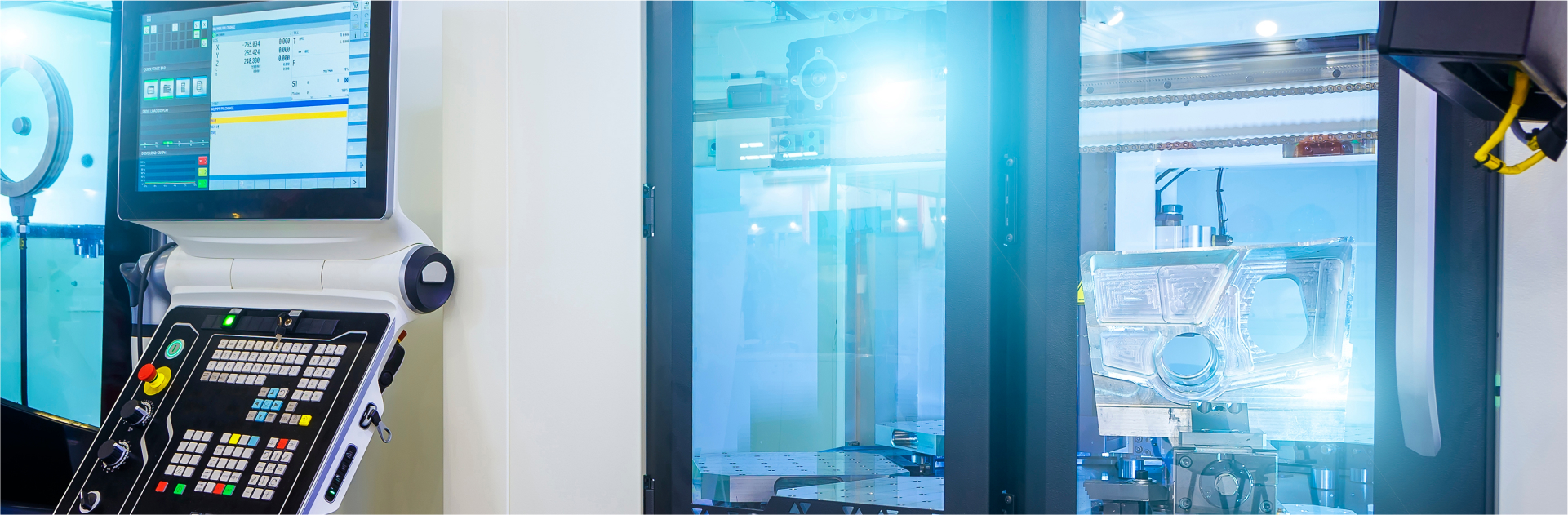

CNC Milling Processing

Custom Rapid Prototyping

Comprehensive Integrated Manufacturing Services

Wei Tian Technology has established a dedicated CNC development department specializing in prototype services. We excel in designing a variety of fixtures and molds, offering a comprehensive range of integrated manufacturing services including material selection, mold fabrication, heat treatment, CNC milling, surface grinding, electroplating, and surface treatment. Our goal is to help customers quickly enter the market and enhance their competitiveness in industries such as drive components, medical equipment, semiconductor equipment, automation equipment, and electronic optical products.

Supporting Processing Techniques: Wire Cutting, Laser Engraving, Double-Sided Surface Grinding, Six-Sided Machining

Supporting Processing Techniques: Wire Cutting, Laser Engraving, Double-Sided Surface Grinding, Six-Sided Machining

Material Hardness Treatment: Normalization, Quenching and Tempering, High Frequency, Nitriding, Vacuum Heat Treatment, Tempering, etc.

Surface Treatment Matching Technologies: Anode, Hard Anode, Nickel Plating, Zinc Plating, Chrome Plating, Professional Baking Paint, Sandblasting, Teflon, PVD, Vacuum Plating, etc.

03

代工製造服務 OEM

原廠委託設計 ODM

聯合設計製造 JDM

Covering everything from design to large-scale production

We provide comprehensive OEM/ODM/JDM solutions for global partners, covering everything from design integration and prototype development to large-scale production of precision parts. Our expertise spans manufacturing, quality control, and the application of new technologies, ensuring the reliable delivery of products.

04

Professional Assembly/Packaging Services

Dedicated Project Services

We can tailor our services to meet customer needs by having dedicated personnel directly liaise with clients. After discussing and communicating,

we provide professional services such as product assembly, testing, inspection, and packaging.

Our Products

Product Categories

Precision Quality, Customized Service

In the CNC machining industry, we are dedicated to providing the highest quality products and services. Our expert team uses the most advanced technology and equipment to ensure that every product meets or exceeds your expectations. We understand the importance of precision and reliability, and we are committed to subjecting each project to rigorous quality inspections to ensure flawless delivery.

Whether your needs are for large-scale production or custom parts, we can provide tailored solutions. Customer satisfaction is our highest priority, and from the start of your order to the final delivery, our professional team will support you throughout the process, ensuring that every requirement is met.

Explore our diverse range of products and experience the perfect blend of quality and service. Your trust is the driving force behind our continuous improvement, and we look forward to working together to create an outstanding future.

Drive Components

(Linear Guides, Linear Blocks)

Transmission components

Various Hardware Components

Hardware parts

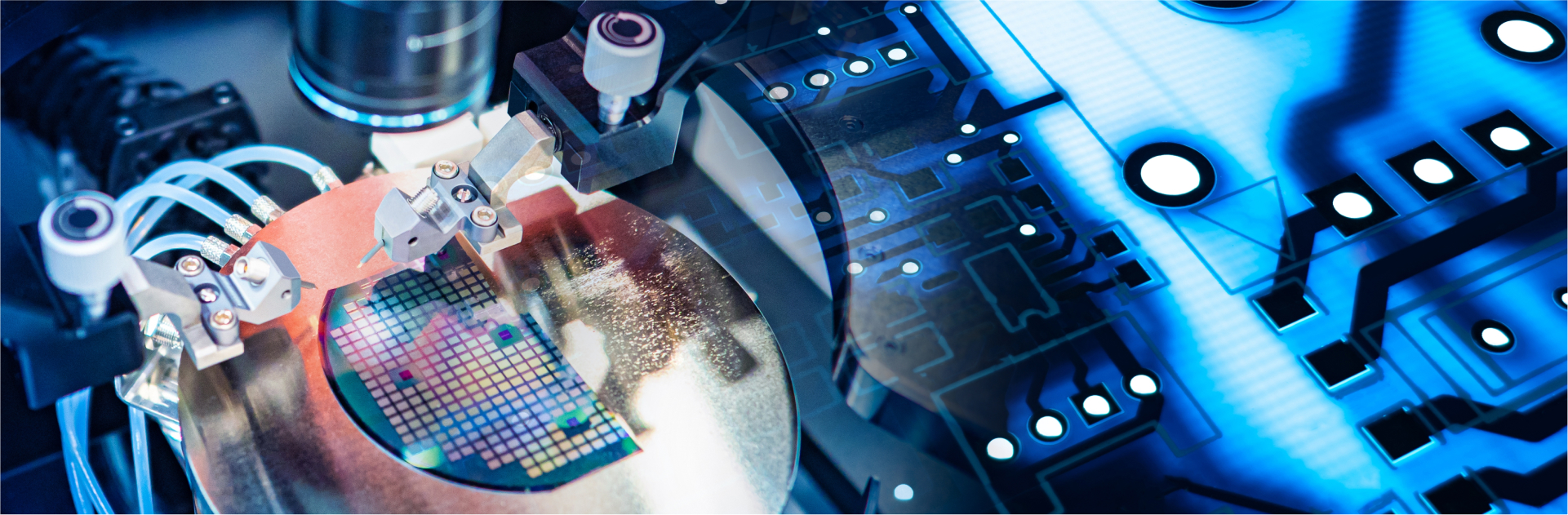

Semiconductor Industry

Semiconductor industry

Machine Tool Industry

Machine tool industry

Optoelectronics Industry

Electronic optics industry

Automation Components

Automation spare parts

Aerospace Industry

Aerospace industry

Hand Tool Industry

Hand tools industry

Automotive Components

Car parts

Medical Components

Medical parts

Service features

Service Features

Upholding the Principle of Integrity

Our company was founded in 2011, and initially began with small-scale processing operations. Through exceptional technology and continuous innovation, we have gradually expanded our business scope, enhancing both our production capacity and product quality. As our business developed, we provided more comprehensive solutions for our clients. We also actively engaged in international market competition and introduced the ISO 9001 Quality Management System certification in 2023 to ensure our products and services meet international standards.

Smart Factory

Our modern facility is equipped with an IoT (Internet of Things) management system, enabling real-time monitoring of machine parameters and anomaly control. This reduces equipment failures and production errors, minimizing defective product losses, and allows for real-time tracking and feedback of production history.

Outstanding Processing Equipment

Our facility uses CNC milling machines from leading Taiwanese brands, known for their high precision, rigidity, and stability. The components used comply with standards set by European, American, and Japanese clients. We also adhere to international ESG (Environmental, Social, and Governance) trends, continually updating and optimizing our equipment to align with these standards.

Strict Precision Control

As environmental conditions shift towards extreme weather, the rate of temperature rise during the processing stage has increased, leading to more significant precision errors due to thermal expansion. Temperature variations during processing can impact finished product quality by up to 35-70%. To address temperature rise issues, all CNC machining equipment in our facility is equipped with Renishaw's tool length measurement systems, which ensure precise control of machining accuracy.

Quality Management

The company has implemented the ISO 9001 Quality Management System (QMS) for internal management, establishing comprehensive SOPs and standardized operating procedures. Alongside professional on-site machining technicians, this enhances product stability.

Contact us

Every question is a driving force for our progress.

Every piece of feedback shapes our future. Contact us, and let’s work together to create a healthier and more promising tomorrow.