緯田科技有限公司

Innovative Technology to Meet All Your Processing Needs

About us

About Wei Tian

Integrity, Responsibility, Innovation

Quality First, Customer Satisfaction

We are a professional technology company with years of experience in manufacturing and processing, dedicated to providing our customers with exceptional technical services and solutions. With our expertise in advanced manufacturing technologies and strict quality control, we have become the preferred partner for leading companies across various industries.

We are committed to a customer-centric approach, consistently providing high-quality products and services. Our goal is to establish long-term partnerships with our clients, working together to advance and develop the industry. Whatever your needs, we are dedicated to offering you the most professional and reliable technical support and services, helping you grow your business and achieve mutual success.

Service

Service

Innovative Technology to Meet All Your Processing Needs

Our company offers a diverse range of technical services, covering every stage from product design and prototyping to mass production. We have a team of skilled professionals who provide customized solutions tailored to client needs. We are committed to ensuring that each project meets customer expectations precisely and is delivered within the agreed timeframe.

Mass Production

CNC Milling Processing

Custom Rapid Prototyping

CNC Milling Processing

Comprehensive Services

Professional Assembly/Packaging Services

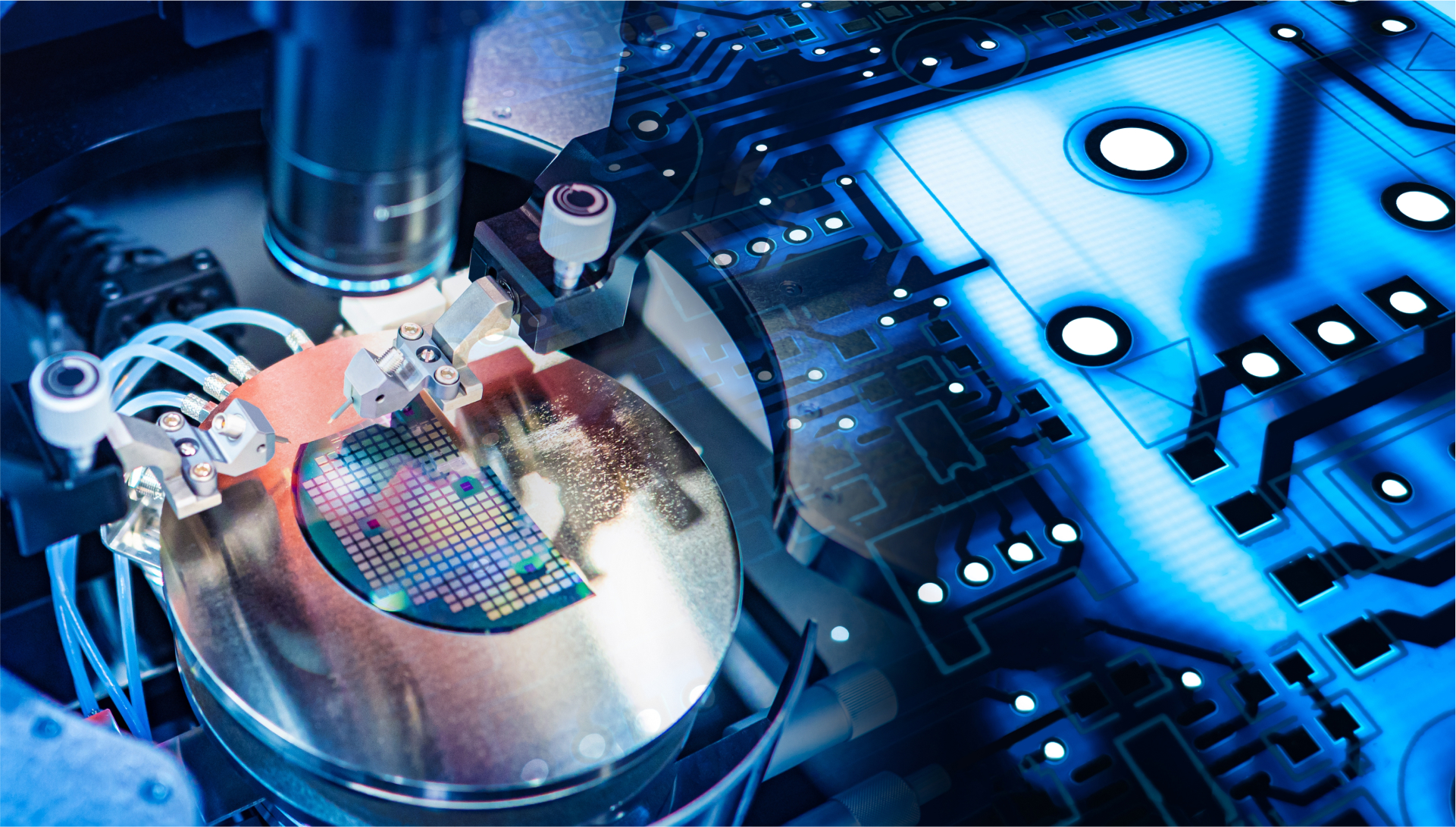

Our Products

Product Categories

Precision Craftsmanship, Exceptional Quality

Our goal is to pursue perfection, with a commitment to providing exquisite craftsmanship and exceptional products. Our services cover a wide range of industry needs, and whether it’s small components or large assemblies, we ensure precise processing.

History

Company History

Upholding the Principle of Integrity

Our company was founded in 2011, and initially began with small-scale processing operations. Through exceptional technology and continuous innovation, we have gradually expanded our business scope, enhancing both our production capacity and product quality. As our business developed, we provided more comprehensive solutions for our clients. We also actively engaged in international market competition and introduced the ISO 9001 Quality Management System certification in 2023 to ensure our products and services meet international standards.

Strict Quality Control

One-Stop Service: From Design to Delivery, Ensuring Peace of Mind

Service features

Service Features

Fast and Efficient, Customer first

While maintaining high quality, we are committed to enhancing production efficiency to guarantee fast delivery. Whether it’s for sample production or mass manufacturing, we complete and deliver within the shortest possible time.

We are committed to a customer-centric approach, continuously improving service quality, and look forward to partnering with you to build a better future. Learn more about our service features and experience the difference that superior quality can bring.

Smart Factory

Our modern facility is equipped with an IoT (Internet of Things) management system, enabling real-time monitoring of machine parameters and anomaly control. This reduces equipment failures and production errors, minimizing defective product losses, and allows for real-time tracking and feedback of production history.

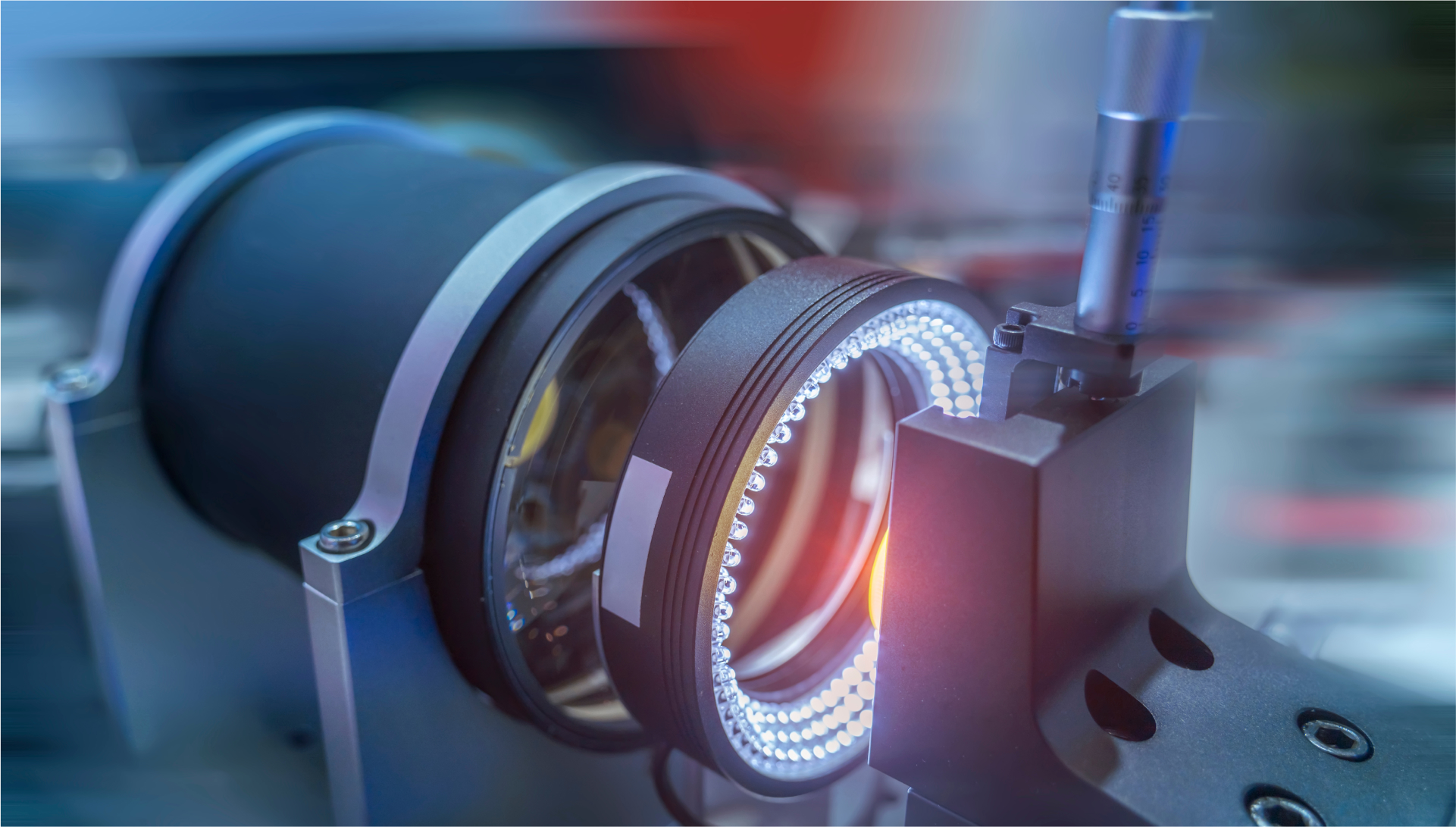

Outstanding Processing Equipment

Our facility uses CNC milling machines from leading Taiwanese brands, known for their high precision, rigidity, and stability. The components used comply with standards set by European, American, and Japanese clients. We also adhere to international ESG (Environmental, Social, and Governance) trends, continually updating and optimizing our equipment to align with these standards.

Strict Precision Control

As environmental conditions shift towards extreme weather, the rate of temperature rise during the processing stage has increased, leading to more significant precision errors due to thermal expansion. Temperature variations during processing can impact finished product quality by up to 35-70%. To address temperature rise issues, all CNC machining equipment in our facility is equipped with Renishaw's tool length measurement systems, which ensure precise control of machining accuracy.

Quality Management

The company has implemented the ISO 9001 Quality Management System (QMS) for internal management, establishing comprehensive SOPs and standardized operating procedures. Alongside professional on-site machining technicians, this enhances product stability.

Contact us

Every question is a driving force for our progress.

Every piece of feedback shapes our future. Contact us, and let’s work together to create a healthier and more promising tomorrow.